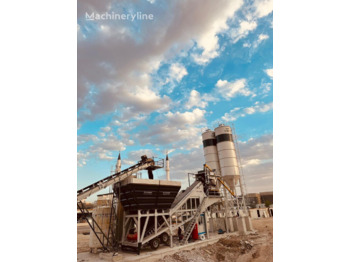

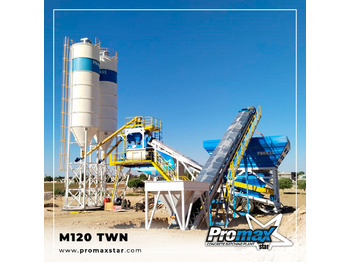

Centrale à béton neuf Plusmix PLUSMİX MT120-TWN Double Chassis -:120m³/hour Mobile Concrete P

Publié: 2mois 25jour(s)

Publié: 2mois 25jour(s)

Avez-vous besoin d'expédition?

1- Aggregate Bunker and weighing belt conveyor : 1 ea

Capacity : 4x30m3 = 120m3

Bunker discharge chute covers : 4 ea/compartment

Sand compartment : 2

Vibrator for each sand compartment : 1ea, OZB 200/3

Pneumatic cylinders : TEKMAK-FMS

Pneumatic valves : SEMAKMATIC – ITALY

FRY Conditioner : SEMAKMATIC – ITALY

Weighing belt conveyor : 1 ea

Loadcells : 4 x 5000kg, KELLY

Conveyor belt : BANTSAN

Size of the belt : 1000 mm x 14.000 mm

Motor –gearbox : 11kW, 1500 pm, GAMAK--DİŞSAN

Emergency stop button : 1 ea

Bearings : SNH series with lubrication grease nipple

Drums : covered with 10mm rubber

Bearings of rollers : standard SKF or ORS

Scraper : V-type, with counterweighs

Vibrators of weighing bunker : OZB 300/3

2- Aggregates transfer belt conveyor : 1 ea

Size of the belt : 1000 mm x 16.420 mm

Conveyor belt : DERBY-BANDSAN

Motor –gearbox : 30kW, 1500 pm, GAMAK--DİŞSAN

Belt slide switch : 4 ea

Belt safety switch : 2 ea

Belt breakage sensor : 1 ea

Emergency stop button : 1 ea

Bearings : SNH series with lubrication grease nipple

Drums : covered with 10mm rubber

Bearings of rollers : standard SKF or ORS

Scraper : V-type, with counterweighs

3 – Main frame

Main frame and steel structure manufactured using high quality steel and workmanship as per ISO9001, CE norms andother applicable international standards and provides height from 4100mm to 4250mm. With an average width of 5000mm, main frame provides easy maneuvering and filling of truck mixers, and easy use of it. Main frame is installed with platform, handrails and stairs.

3.1-Cement weighing bunker : 1 ea

Weighing capacity : 2000kg

Loadcells : 3 x 1000kg, KELLY

Valves : BV1FS300NN D=300mm

Driver : ACP13, Pneumatic actuator

Vibrator : 1ea, OZB 100/3

3.2-Water weighing bunker : 1 ea

Weighing capacity : 1000L

Valves : BV1FS250NN – D= 250mm

Driver : ACP13, Pneumatic actuator

Loadcells : 2x1000kg, KELLY

3.3-Additives weighing bunker : 1 ea

Capacity : 50 kg

Loadcells : 1 ea, 100kg, KELLY

Valves : 1 ½ ’’

3.4-Compressed air installations : 1 ea

Brand : AKKOMP

Air tank : 1850L/min flow and 1000L

Working pressure : 8.5 bar

Motor power : 7.5kW

4 – Mixer - Twinshaft : 1 ea

Origin : PLUSMİX/TURKEY

Model : PLS TWN 4500-3000

Brand : PLUSMİX / Twinshaft

Type : 4500 / 3000

Loading capacity : 4500L

Compacted fresh concrete : 3000L

Motor-gearbox : 2x55 kW, GAMAK – ERMAKSAN

Voltage : 380V-50 Hz

Discharge cover cylinder - brand and type : PLUSMİX, hydraulic

Discharge covers : 1 ea

Central lubrication system : ILC automatic central lubrication

Mixer base wear plates : ST - 52

Mixer side wall wear plates : Ni- hard, special hard-cast

Mixer mixing arms : Ni- hard, special hard-cast

Mixer discharge system : Hydraulic

Mixer safety system : Safety switch of service cover

: Emergency stop button

: Digital mixer control system (with an alarm)

Availability to follow the automatic lubrication system on the PC. Water dispenser

5 .Automation System and Control Panel

PLUSMİX brand concrete power plant automation systems are used in PLUSMIX concrete power plants. All system control is provided by Kartal or lion (display control panel ) designed by Turkish engineers. The PLC modules used in system control operate only as interfaces. The indicators used in weight measurement are high-tech and small-size, fast, responsive and accurate. The key materials used in the MCC control panel are SIEMENS brand. All control cables on the control panel are labeled on the ports. In this way, fault detection and monitoring can be done more easily.

Concrete production is completely automated through the computer. If necessary, the system can be interfered with using a mouse from the SCADA screen. The system in the SCADA program can be designed according to the characteristics and type of the official plant.

In addition to fast and reliable operation of the BETOSYSTEM SCADA program, it is also possible to access statistical and detailed production information. All reports made on the basis of the most preferred detailed production, prescription, customer, carrier and material can be obtained in detail from the computer screen or printer within the desired date range. In addition, if desired, the report can be designed with a custom reporting option. Our automation system guarantees accurate and accurate production as well as continuous and reliable operation with all high quality equipment.

SCADA PROGRAM

Computerized control system and control (SCADA) system

PLUSMİX; concrete production SCADA program ( Beto system ) is a process control program specially developed for concrete plants because the indicator, PLC, is a much faster communication between PC. The EAGLE indicator and control device, which is developed only for concrete plants, contains all the equipment required for the control of the plant. With its electronic buttons and Universal visualizations on Eagle, it provides ease of use to all operators around the world. All production is monitored visually through SCADA program, intervene if necessary, order, recipe, parameters, inventory acceptance, failure tracking and reporting details of the production can be taken. It is extremely easy to use and can be monitored remotely if desired. All the records of the production can be transferred to a specified PC continuously.

6 – Command cabin : 1 ea

Size : 2200 mm x 1500 mm x 2500 mm

Air conditioner : 1 ea

Outer surface : painted and galvanized steel plates

Inner surface : 12mm, wooden plate

Isolation : side walls - hard polystyrene

Windows : PVC

Note: Electrical wiring, sockets and switches are included in the cabin.

Avez-vous besoin d'expédition?

Obtenir un devis d'expédition

Avez-vous besoin d'expédition?

Obtenir un devis d'expédition